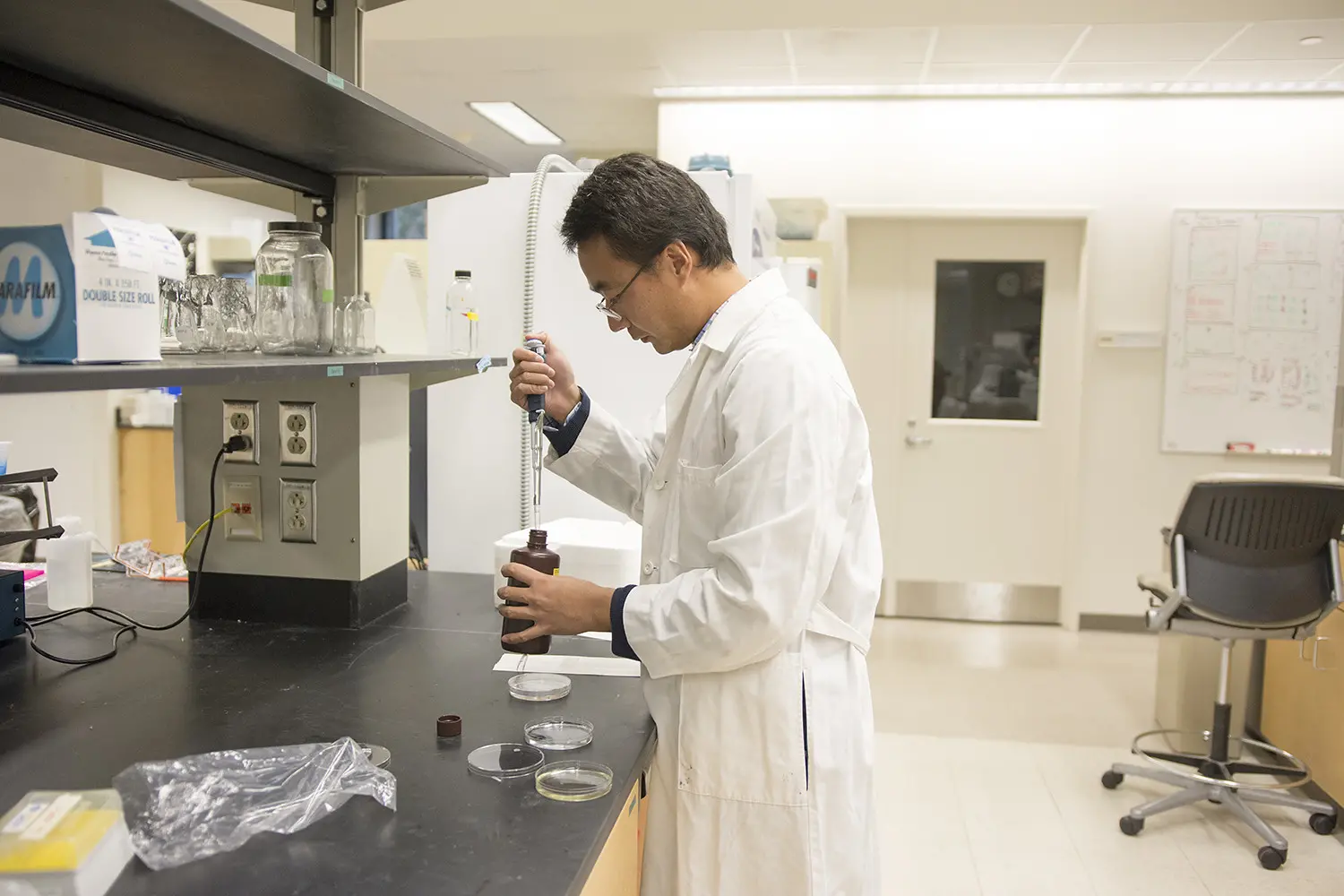

Microorganisms are increasingly used to produce biofuels and chemicals. However, developing robust microorganisms for the economical production of biofuels and bioproducts from low-cost, often-recalcitrant feedstocks on a large scale with high titers, rates, and yields remains a significant challenge. Researchers in this theme are tackling this with non-model organisms.

The Challenges

- Lack of known enzymes with desired activity and substrate specificity for the synthesis of target natural or non-natural compounds

- Time-consuming and expensive design-build-test-learn cycle for metabolic engineering

- Poor understanding of how native metabolism and physiology constrains the production of non-natural compounds

- Difficulty identifying compounds that can be efficiently produced in living organisms

The Solutions

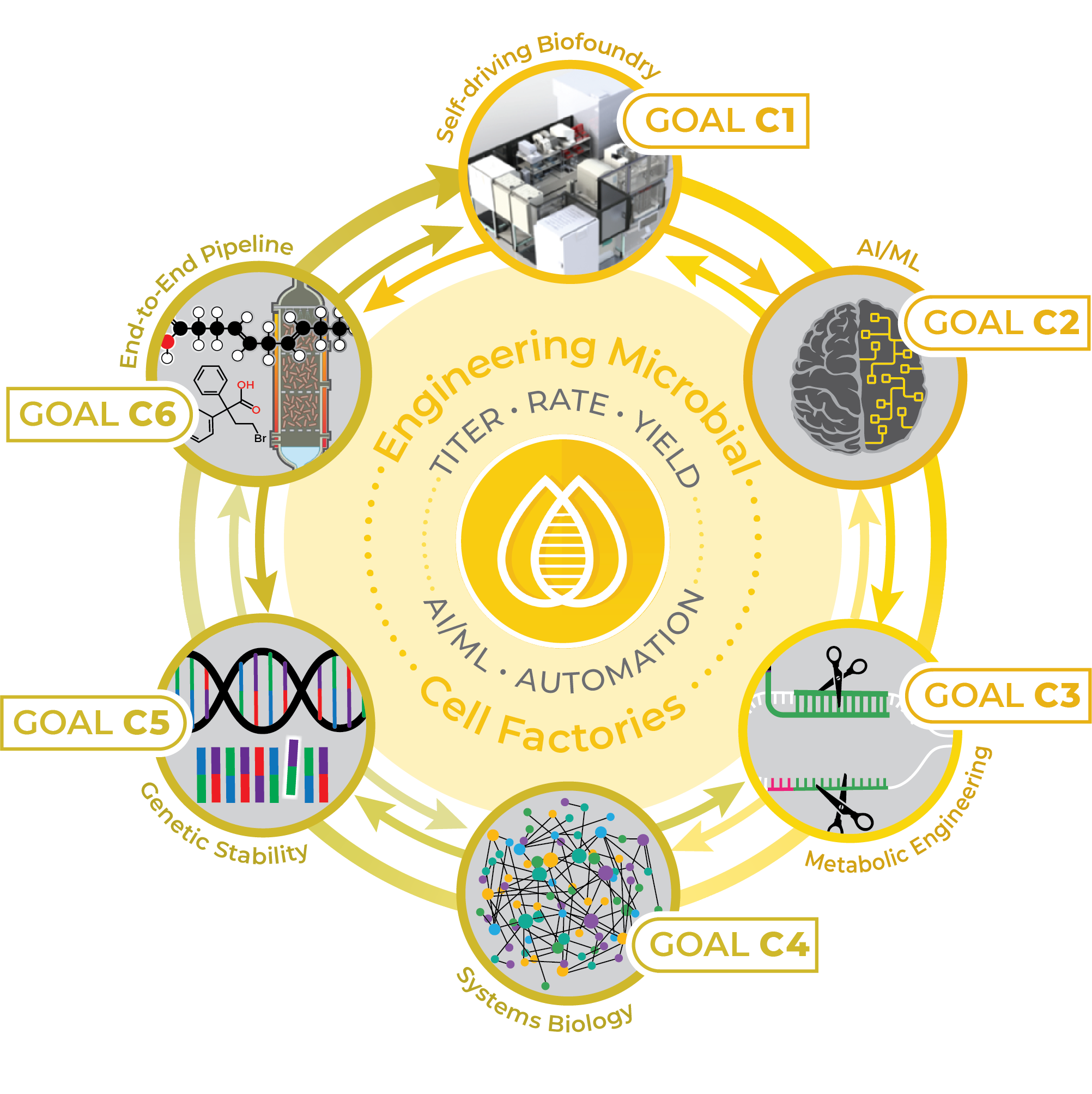

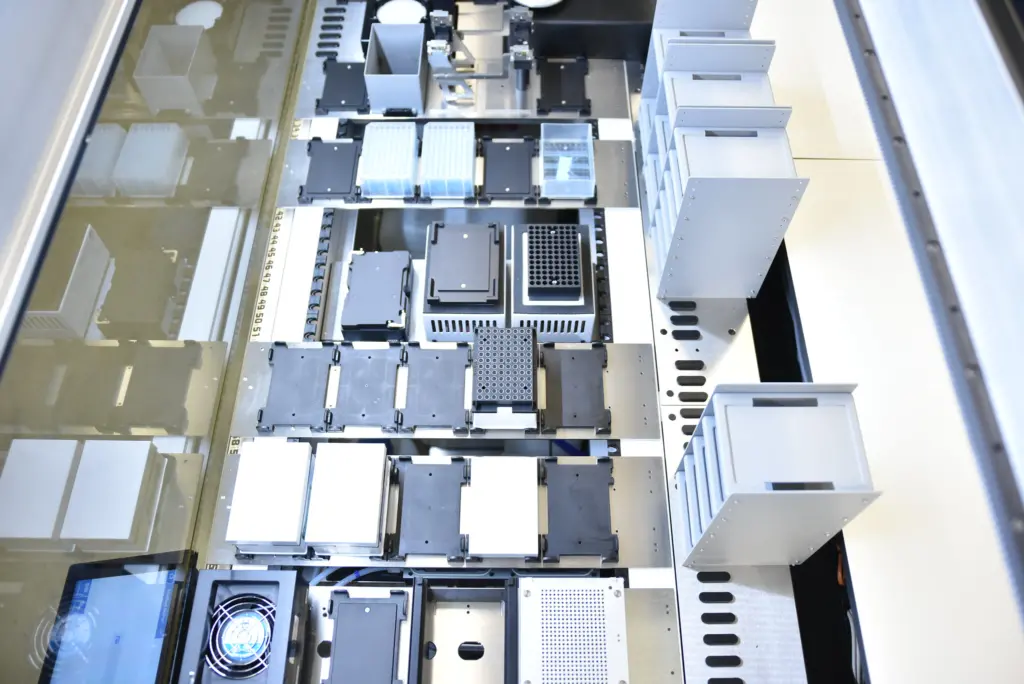

Researchers in the Conversion theme will further develop a versatile, automated “biofoundry” for rapidly engineering microbial strains that can efficiently produce diverse, high-value molecules such as biodiesel, organic acids, jet fuels, lubricants, and alcohols. Using the design-build-test-learn framework, research in the Conversion theme will overcome the challenges associated with engineering microbial cell factories to produce biofuels and bioproducts.

The Goals

- Accelerate self-driving biofoundry for biosystems design (C1)

- Advance AI/ML algorithms for biosystems design (C2)

- Metabolically engineer non-model yeasts for greater production of fuels and chemicals (C3)

- Progress quantitative, systems-level understanding of non-model yeast metabolism (C4)

- Characterize and engineer genetic stability for large-scale fermentation (C5)

- Develop an end-to-end pipeline for microbial production of fuels and chemicals (C6)