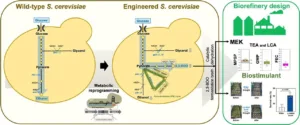

Rewiring Yeast Metabolism for Producing 2,3-Butanediol and Two Downstream Applications: Techno-Economic Analysis and Life Cycle Assessment of Methyl Ethyl Ketone (MEK) and Agricultural Biostimulant Production

Themes: Conversion, Sustainability

Keywords: Economics, Metabolomics

Citation

Lee, J.W., Bhagwat, S.S., Kuanyshev, N., Cho, Y.B., Sun, L., Lee, Y.G., Cortés-Peña, Y.R., Li, Y., Rao, C.V., Guest, J.S., Jin, Y.S. Aug. 29, 2022. Data from: “Rewiring Yeast Metabolism for Producing 2,3-Butanediol and Two Downstream Applications: Techno-Economic Analysis and Life Cycle Assessment of Methyl Ethyl Ketone (MEK) and Agricultural Biostimulant Production.” GitHub Repository.

Overview

Rising concerns for sustainability and global climate change have driven the development of sustainable production pathways for biofuels and chemicals from lignocellulosic biomass via integrated biological and chemical processes. We constructed an engineered Saccharomyces cerevisiae capable of producing 2,3-butanediol (2,3-BDO) from glucose without accumulating ethanol and glycerol, which hinder downstream processing of 2,3-BDO, through extensive metabolic reprogramming. Specifically, we introduced heterologous 2,3-BDO biosynthetic enzymes and deleted the major isozymes of ethanol and glycerol biosynthetic enzymes. In addition, we introduced an NAD+ regenerating Pyruvate-Malate (PM) cycle and enhanced the NAD+ regenerating capability of the PM cycle to resolve the redox imbalance from the deletion of ethanol and glycerol production pathways. The resulting engineered yeast produced 109.9 g/L of 2,3-BDO with a productivity of 1.0 g/L/h and a yield of 0.36 g/g glucose in a fed-batch fermentation. We also conducted techno-economic analysis (TEA) and life cycle assessment (LCA) of the production of methyl ethyl ketone (MEK) through catalytic dehydration of 2,3-BDO. A TEA based on the experimental results indicated that the minimum product selling price (MPSP) was estimated to be $1.90/kg. Regarding cradle-to-grave LCA, 100-year global warming potential (GWP100) and fossil energy consumption (FEC) were found to be 0.37 kg CO2 eq/kg and 3.1 MJ/kg, respectively. These results demonstrated the feasibility of cost-competitive and sustainable bio-based MEK production via yeast fermentation. In addition, we explored the possibility of using the fermentation broth containing 2,3-BDO as a biostimulant inducing drought tolerance in plants. As a result, the yeast 2,3-BDO fermentation broth can induce drought tolerance in Arabidopsis thaliana without a complicated purification process.