Renewable Linear Alpha-Olefins by Base-Catalyzed Dehydration of Biologically-Derived Fatty Alcohols

Themes: Conversion, Sustainability

Keywords: Catalysis, Modeling

Citation

McClelland, D.J., Wang, B., Cordell, W., Cortes-Peña, Y., Gilcher, E.B., Zhang, L., Guest, J.S., Pfleger, B.F., Huber, G., Dumesic, J.A. May 4, 2021. Data from: “Renewable Linear Alpha-Olefins by Base-Catalyzed Dehydration of Biologically-Derived Fatty Alcohols.” University of Illinois Urbana-Champaign. DOI: 10.13012/B2IDB-4438634_V1.

Overview

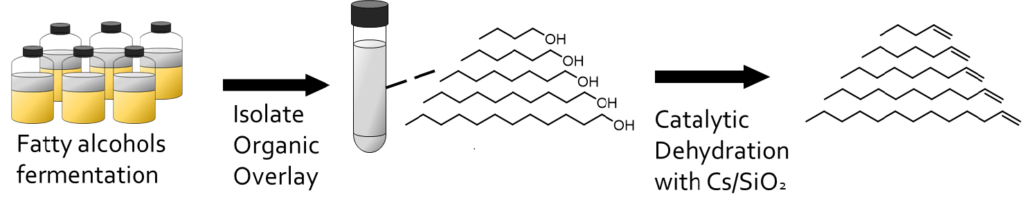

Base catalysts were studied for the dehydration of fatty alcohols to linear alpha olefins (LAOs). For the gas phase dehydration of 1-octanol to 1-octene, 15% Cs/SiO2 catalyst was 56% selective at 10% conversion. Diluting a feed of C8, C10, and C14 fatty alcohols to 50% in undecane increased the selectivity to alpha olefins to 77–99%. 15% Cs/SiO2 was further investigated for the gas phase dehydration of a 4.2 g L−1 mixed C8–C14 fatty alcohol in tridecane feed and showed linear alpha olefin selectivities of 78–100% at initial conversions of 51–91% with the conversion lowering to 32–77% over 30 h. Catalytic activity was totally regenerated through calcination. A feed of biologically derived alcohols was produced with E. coli strain CM24 transformed with three plasmids (pBTRCk–pVHb–maACR, pACYC–pVHb–seFadBA, pTRC99A–pVHb–tdTER–fdh) which yielded a 5.5 g L−1 of C8–C14 fatty alcohol in tridecane. This biologically-derived feed was successfully dehydrated to linear alpha olefins over 15% Cs/SiO2 at selectivities of 60–100% with initial conversions of 35–75% which decreased to 22–55% over 30 h. Techno-economic analysis (TEA) of the integrated process for fatty alcohol production and subsequent dehydration to alpha olefins was conducted across the potential fermentation TRY (titer, rate, yield) landscape. Baseline fermentation performance resulted in a minimum product selling price (MPSP) double the market price for LAOs due to low titers and high costs associated with managing water and tridecane solvent flows through the system. However, targeted improvements in fermentation performance (e.g., achieving 40 g L−1 titer, 0.5 g L−1 h−1 productivity, 80% theoretical yield) can enable financially viable production of biologically derived LAOs.

Data

Illinois Data Bank: Includes design requirements, capital costs, stream tables, economic metrics, alcohol conversions