Reactive Species and Reaction Pathways for the Oxidative Cleavage of 4-Octene and Oleic Acid with H2O2 over Tungsten Oxide Catalysts

Themes: Conversion

Keywords: Catalysis

Citation

Yun, D., Ayla, E.Z., Bregante, D.T., Flaherty, D.W. Feb. 24, 2021. “Reactive Species and Reaction Pathways for the Oxidative Cleavage of 4-Octene and Oleic Acid with H2O2 over Tungsten Oxide Catalysts.” University of Illinois Urbana-Champaign. DOI: 10.13012/B2IDB-6782711_V1.

Overview

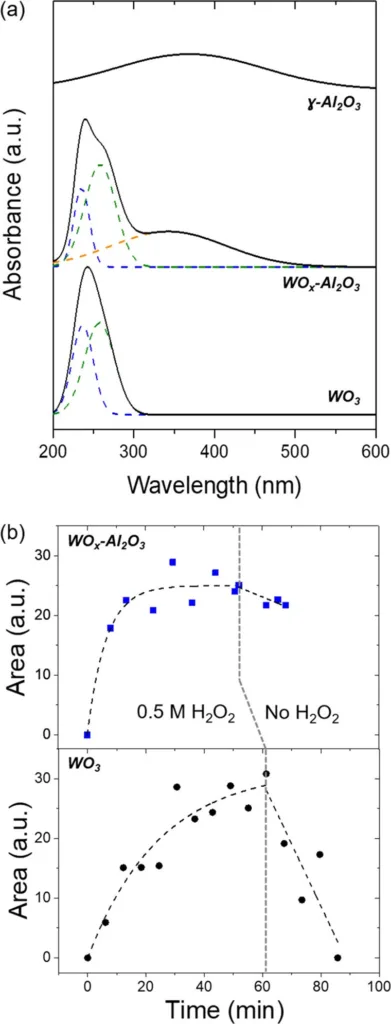

Oxidative cleavage of carbon–carbon double bonds (C═C) in alkenes and fatty acids produces aldehydes and acids valued as chemical intermediates. Solid tungsten oxide catalysts are low cost, nontoxic, and selective for the oxidative cleavage of C═C bonds with hydrogen peroxide (H2O2) and are, therefore, a promising option for continuous processes. Despite the relevance of these materials, the elementary steps involved and their sensitivity to the form of W sites present on surfaces have not been described. Here, we combine in situ spectroscopy and rate measurements to identify significant steps in the reaction and the reactive species present on the catalysts and examine differences between the kinetics of this reaction on isolated W atoms grafted to alumina and on those exposed on crystalline WO3 nanoparticles. Raman spectroscopy shows that W–peroxo complexes (W–(η2-O2)) formed from H2O2 react with alkenes in a kinetically relevant step to produce epoxides, which undergo hydrolysis at protic surface sites. Subsequently, the CH3CN solvent deprotonates diols to form alpha-hydroxy ketones that react to form aldehydes and water following nucleophilic attack of H2O2. Turnover rates for oxidative cleavage, determined by in situ site titrations, on WOx–Al2O3 are 75% greater than those on WO3 at standard conditions. These differences reflect the activation enthalpies (ΔH‡) for the oxidative cleavage of 4-octene that are much lower than those for the isolated WOx sites (36 ± 3 and 60 ± 6 kJ·mol–1 for WOx–Al2O3 and WO3, respectively) and correlate strongly with the difference between the enthalpies of adsorption for epoxyoctane (ΔHads,epox), which resembles the transition state for epoxidation. The WOx–Al2O3 catalysts mediate oxidative cleavage of oleic acid with H2O2 following a mechanism comparable to that for the oxidative cleavage of 4-octene. The WO3 materials, however, form only the epoxide and do not cleave the C–C bond or produce aldehydes and acids. These differences reflect the distinct site requirements for these reaction pathways and indicate that acid sites required for diol formation are strongly inhibited by oleic acids and epoxides on WO3 whereas the Al2O3 support provides sites competent for this reaction and increase the yield of the oxidative cleavage products.

Data

- UV-vis spectra

- Turnover rates for oxidative cleavage

- In and Ex situ Raman spectra

- Concentration and selectivity calculations