Production of Designer Xylose-Acetic Acid Enriched Hydrolysate from Bioenergy Sorghum, Oilcane, and Energycane Bagasses

Themes: Conversion

Keywords: Biomass Analytics, Feedstock Bioprocessing, Hydrolysate

Citation

Cheng, M.H., Singh, S., Carr Clennon, A.N., Dien, B.S., Singh, V. July 1, 2023. “Designer Xylose-Acetic Acid Enriched Hydrolysate from Bioenergy Sorghum, Oilcane, and Energycane Bagasses.” Bioresource Technology. DOI: 10.1016/j.biortech.2023.129104.

Overview

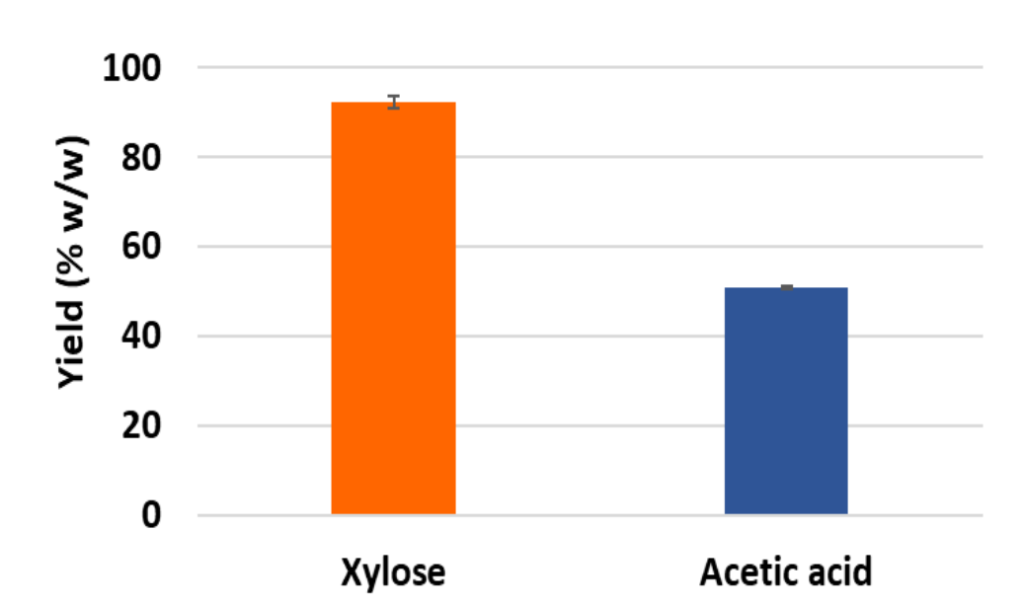

Xylan accounts for up to 40% of the structural carbohydrates in lignocellulosic feedstocks. Along with xylan, acetic acid in sources of hemicellulose can be recovered and marketed as a commodity chemical. Through vibrant bioprocessing innovations, converting xylose and acetic acid into high-value bioproducts via microbial cultures improves the feasibility of lignocellulosic biorefineries. Enzymatic hydrolysis using xylanase supplemented with acetylxylan esterase (AXE) was applied to prepare xylose-acetic acid enriched hydrolysates from bioenergy sorghum, oilcane, or energycane using sequential hydrothermal-mechanical pretreatment. Various biomass solids contents (15 to 25%, w/v) and xylanase loadings (140 to 280 FXU/g biomass) were tested to maximize xylose and acetic acid titers. The xylose and acetic acid yields were significantly improved by supplementing with AXE. The optimal yields of xylose and acetic acid were 92.29% and 62.26% obtained from hydrolyzing energycane and oilcane at 25% and 15% w/v biomass solids using 280 FXU xylanase/g biomass and AXE, respectively.

Data

- 15%, 20%, and 25% loading data

- Acetic acid, glucose, xylose yields

- Chemical compositions