Increasing Ethanol Yield through Fiber Conversion in Corn Dry Grind Process

Themes: Conversion

Keywords: Feedstock Bioprocessing

Citation

Kurambhatti, C.V., Kumar, D., Rausch, K.D., Tumbleson, M.E., Singh, V. Sept. 11, 2018. “Data from Increasing Ethanol Yield through Fiber Conversion in Corn Dry Grind Process.” University of Illinois Urbana-Champaign. DOI: 10.13012/B2IDB-0090776_V1.

Overview

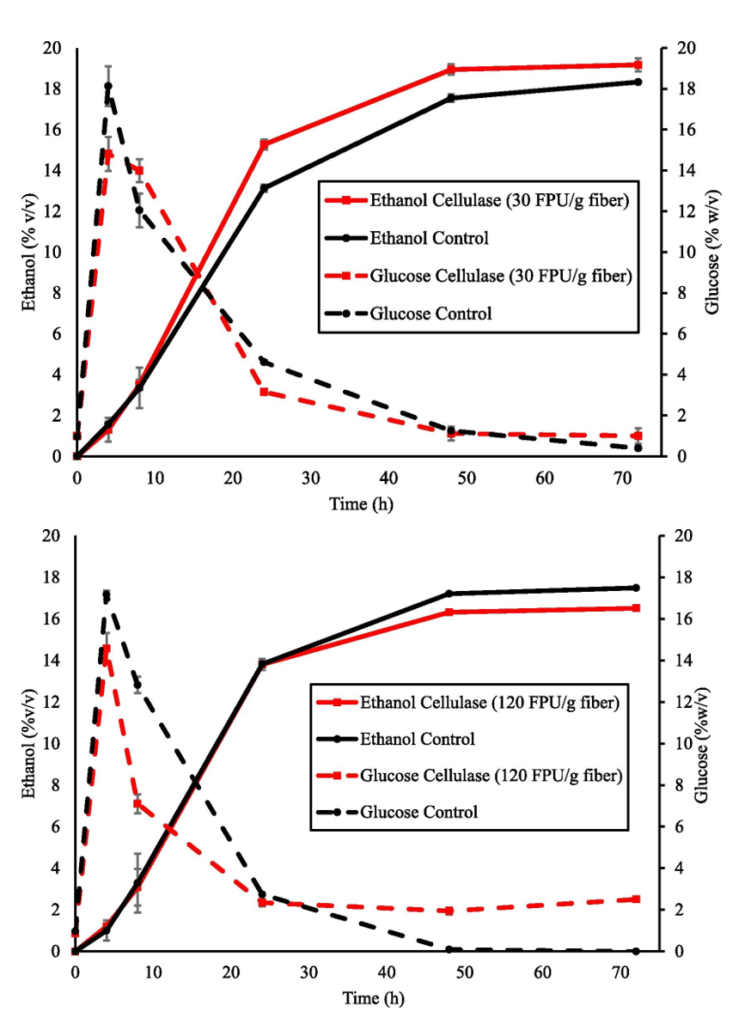

Conversion of corn fiber to ethanol in the dry grind process could increase ethanol yields, reduce downstream processing costs and improve overall process profitability. This work investigates the in-situ conversion of corn fiber into ethanol (cellulase addition during simultaneous saccharification and fermentation) during dry grind process. Addition of 30 FPU/g fiber cellulase resulted in 4.6% increase in ethanol yield compared to the conventional process. Use of excess cellulase (120 FPU/g fiber) resulted in incomplete fermentation and lower ethanol yield compared to the conventional process. Multiple factors including high concentrations of ethanol and phenolic compounds were responsible for yeast stress and incomplete fermentation in excess cellulase experiments.

Data

Illinois Data Bank includes:

- Ethanol and Glucose Profiles

- Effect of cellulose addition on conventional dry grid process