Impact of Non-Irrigation on 1G and 2G Bioethanol Potential of Oilcane Feedstock: A Field to Fuel Pipeline Study

Themes: Conversion, Feedstock Production

Keywords: Biomass Analytics, Feedstock Bioprocessing, Oilcane, Sugar Accumulation

Citation

Deshavath, N.N., Kannan, B., Liu, H., Woodruff., W., Shanklin, J., Altpeter, F., Singh, V. Jan. 4, 2025. Data from: “Impact of Non-Irrigation on 1G and 2G Bioethanol Potential of Oilcane Feedstock: A Field to Fuel Pipeline Study.” University of Illinois Urbana-Champaign. DOI: 10.13012/B2IDB-6728019_V1.

Overview

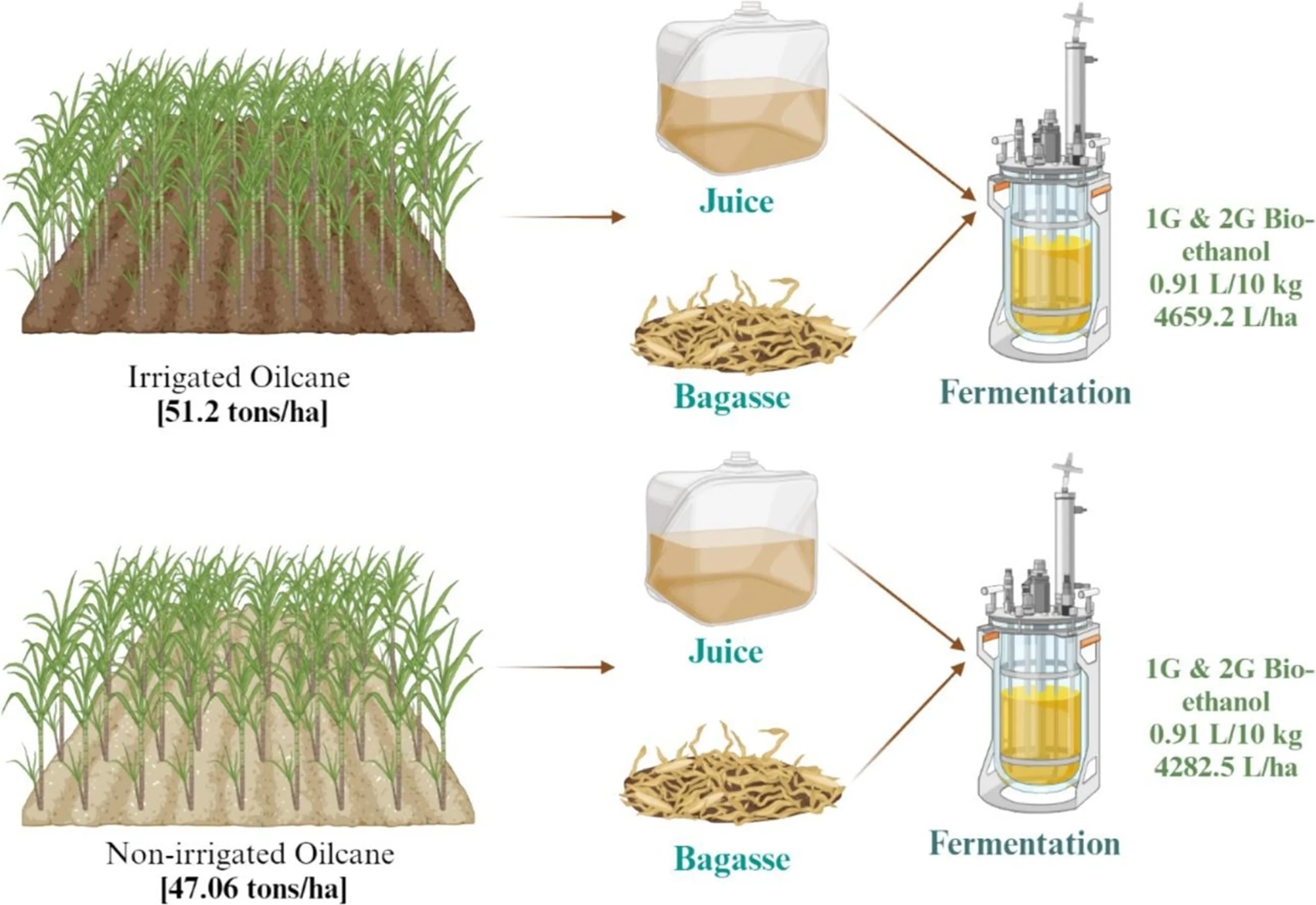

This study evaluates the bioethanol potential in response to irrigation (IR) and non-irrigation (NIR) of oilcane (OC) during a seasonal drought prior harvest. The juice was extracted through mechanical pressing of stems and fermented by Ethanol Red® yeast to produce first-generation bioethanol. Hydrothermal pretreatment followed by enzymatic hydrolysis of bagasse was performed to produce monomeric sugars from structural carbohydrates. The hydrolysates were fermented with engineered yeast for second-generation bioethanol production. The irrigated oilcane juice (276.3 ± 8.9 g/L) constitutes higher sugar concentrations than non-irrigated oilcane juice (236.5 ± 2.2 g/L). The enzymatic hydrolysis of IR-OC and NIR-OC pretreated bagasse yielded similar concentrations of 247.5 ± 2.22 and 249.7 ± 4.98 g/L fermentable sugars. Industry-relevant bioethanol titers of ≥99 g/L and ≥75 g/L were achieved from juice and hydrolysates, respectively. Therefore, the non-irrigation regime did not impact the 1G and 2G bioethanol titers. However, the overall bioethanol yield can be lower due to the reduction of stem yield (8 %) per hectare.

Data

Illinois Data Bank includes:

- Sugar yields

- Fermentation profiles

- Ethanol productivity

- Sugar utilization rates