Evaluation of 1,2-Diacyl-3-Acetyl Triacylglycerol Production in Yarrowia lipolytica

Themes: Conversion, Sustainability

Keywords: Biomass Analytics, Lipidomics, Metabolomics

Citation

Yan, Q., Jacobson, T.B., Ye, Z., Cortés-Pena, Y.R., Bhagwat, S.S., Hubbard, S., Cordell, W.T., Oleniczak, R.E., Gambacorta, F.V., Vazquez, J.R., Shusta, E.V., Amadon-Noguez, D., Guest, J.S., Pfleger, B.F. Jan. 7, 2023. “Data for Evaluation of 1,2-Diacyl-3-Acetyl Triacylglycerol Production in Yarrowia lipolytica.” University of Illinois Urbana-Champaign. DOI: 10.13012/B2IDB-7554126_V1.

Overview

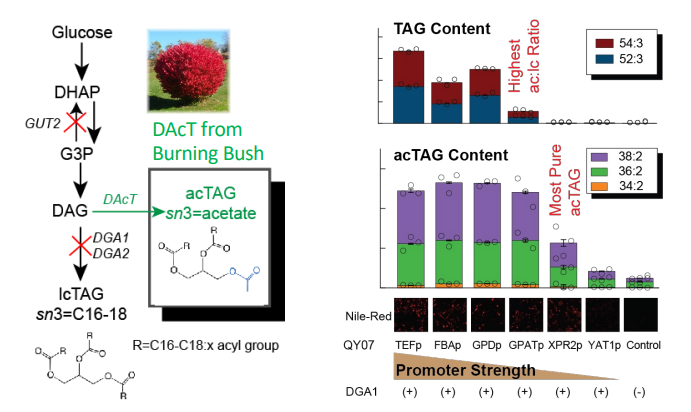

Plants produce many high-value oleochemical molecules. While oil-crop agriculture is performed at industrial scales, suitable land is not available to meet global oleochemical demand. Worse, establishing new oil-crop farms often comes with the environmental cost of tropical deforestation. The field of metabolic engineering offers tools to transplant oleochemical metabolism into tractable hosts while simultaneously providing access to molecules produced by non-agricultural plants. Here, we evaluate strategies for rewiring metabolism in the oleaginous yeast Yarrowia lipolytica to synthesize a foreign lipid, 3-acetyl-1,2-diacyl-sn-glycerol (acTAG). Oils made up of acTAG have a reduced viscosity and melting point relative to traditional triacylglycerol oils making them attractive as low-grade diesels, lubricants, and emulsifiers. This manuscript describes a metabolic engineering study that established acTAG production at g/L scale, exploration of the impact of lipid bodies on acTAG titer, and a techno-economic analysis that establishes the performance benchmarks required for microbial acTAG production to be economically feasible.

Data

- Feedstock Compositions

- Bioreactor Specs

- Biorefinery Operating Costs