As the global population grows, the demand for food and energy is increasing even as extreme weather events make crops more vulnerable to stress. While traditional breeding takes years to develop more resilient crops, plant bioengineering offers a faster, more precise way to improve traits for higher yields and better stress tolerance.

But engineering plants to enhance their helpful traits is a complex process demanding significant time and labor.

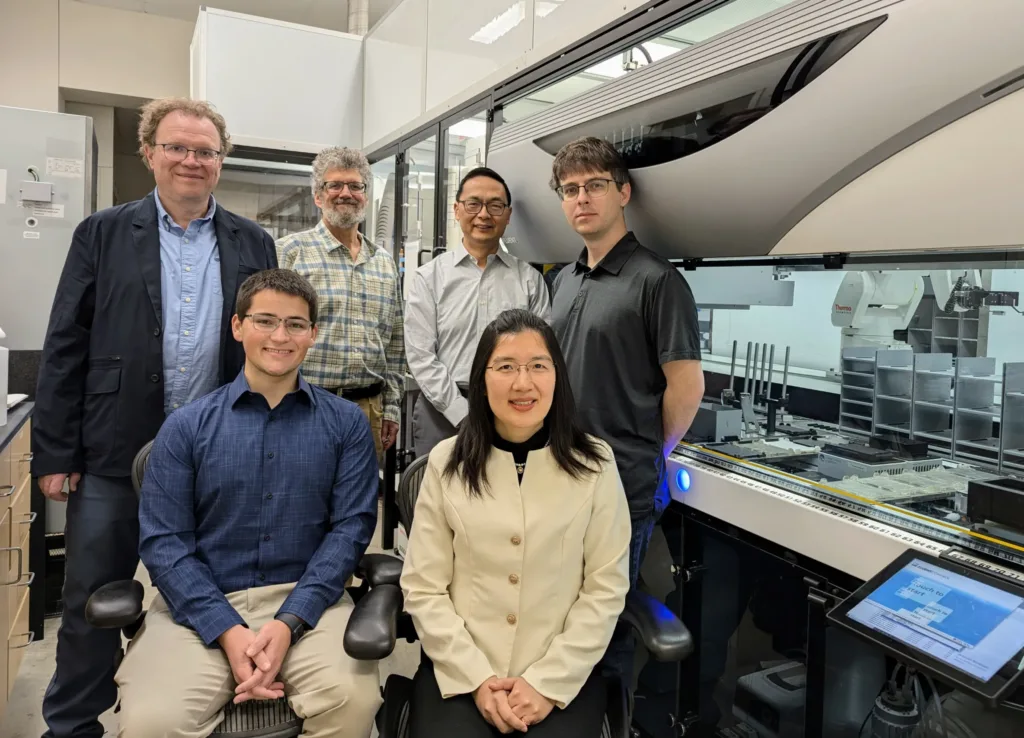

In a major breakthrough, a team at the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) found a way to accelerate this process using robots. Researchers deployed a biofoundry – a laboratory integrating robotics, computer-aided design, and informatics – to make genetically engineered plants and used it to boost oil production in plant cells and even whole plants.

This fast, automated, scalable, high-throughput pipeline for plant bioengineering, or FAST-PB, can be scaled up to improve the speed and productivity of synthetic plant biology, genome editing, and metabolic engineering. The advance will help scientists quickly improve valuable plant traits, such as increasing oil production and optimizing photosynthesis.

“If we can use robots for plant bioengineering, that is a game changer. Automating plant transformation will allow us to develop better bioenergy crops and do it more quickly,” said CABBI Co-PI Matthew Hudson, Professor in the Department of Crop Sciences and the Carl R. Woese Institute for Genomic Biology (IGB) at the University of Illinois Urbana-Champaign.

This study, published in The Plant Cell, was led by a team of CABBI scientists at Illinois in collaboration with researchers at the University of Nebraska-Lincoln (UNL) and Brookhaven National Laboratory who are also part of CABBI, a U.S. Department of Energy (DOE) Bioenergy Research Center. At Illinois, Hudson worked with lead author and Research Scientist Jia Dong of Crop Sciences and IGB; Co-PI Jonathan Sweedler, Professor in the Department of Chemistry and IGB; Ph.D. candidate Seth Croslow of Chemistry; and Co-PI Huimin Zhao, Professor in the Department of Chemical and Biomolecular Engineering and IGB; as well as other researchers.

The CABBI team focused on engineering plants to enhance production of vegetative lipids, a promising avenue to improve global plant oil production without the need for increased fertilizer or land use. Achieving stable lipid production in the tissues of plant biomass requires the engineering and expression of multiple genes, and prototyping these multi-gene constructs is a rate-limiting step in developing next-generation bioenergy crops.

To overcome that hurdle, the team utilized the Illinois Biological Foundry for Advanced Biomanufacturing (iBioFAB) at IGB. Biofoundries improve efficiency and reduce the amount of time and labor required for these experiments. The iBioFAB has been used successfully to automate other synthetic biology processes, such as plasmid assembly, yeast genome editing, and antimicrobial discovery, paving the way for its application in plant genome editing technologies.

The CABBI team combined iBioFAB with single-cell metabolomics to engineer plant genomes and characterize cellular effects, which has never been done before. Metabolomics is the study of chemical processes involving metabolites, the molecular products of cell metabolism that are sometimes called chemical fingerprints.

Researchers created three automated processes using the biofoundry’s multiple robots to speed up the design and testing of genetic changes in plants. The first involved automating protoplast isolation and gene editing, letting scientists study gene functions quickly in plant cells without cell walls. The researchers also automated plant tissue culture, boosting lipid production and allowing them to make whole engineered plants; results showed a significant increase in the number and size of oil droplets in engineered plants.

The third process combined the automated biofoundry with a method called single-cell mass spectrometry (MALDI-MS) that allows scientists to measure all the chemicals within the cells. It uses AI-assisted data analysis to efficiently distinguish between gene edited and non-edited cells.

“Profiling the chemical differences between individual plant cells allows us to measure desired plant characteristics such as lipid production without the confounding impact of using populations of cells,” Sweedler said.

FAST-PB revolutionizes plant bioengineering by integrating automation, synthetic biology, and single-cell lipidomics, dramatically accelerating genome editing and metabolic engineering — ushering in a new era of high-throughput, precision-driven plant transformation.

“Our work is a major step in plant bioengineering, reducing labor, time, and costs while speeding up discoveries in plant genomics and synthetic biology,” Dong said. “This means we can quickly create plants that produce more food and bioenergy, helping to address food and energy security, reduce reliance on imported fuels, and build a more profitable agricultural system.

The large-scale production of biofuels depends on improving plant-based energy sources. By automating key steps, this research accelerates the development of bioenergy crops with enhanced oil production, resilience, and efficiency, paving the way for more resilient and scalable biofuel production.

The advances support CABBI’s goal to improve plant-based biofuels by enabling faster and more efficient modifications to key metabolic pathways. The ability to increase oil production in plants through automated transformation and high-throughput genomic editing and screening aligns with CABBI’s objective of producing resilient biofuels and bioproducts more efficiently.

More broadly, the work contributes to the development of scalable, cost-effective, and automated strategies for optimizing bioenergy crops. By reducing the time, labor, and costs associated with plant transformation and metabolic engineering, this research accelerates the development of bioengineered crops with improved energy storage, resilience, and yield, ultimately supporting the transition to a more bio-based economy.

Other co-authors on this study included CABBI Co-PI Edgar Cahoon and Senior Research Associate Kiyoul Park at UNL; CABBI Co-PI John Shanklin and Jantana Blanford at Brookhaven; and Stephan Lane, Daniel C. Castro, Shuaizhen Zhou, Steven Burgess, and Mike Root at Illinois.

– Article by CABBI Communications Specialist Julie Wurth